#uv cured

Explore tagged Tumblr posts

Text

I have found that painting my nails is really therapeutic for me and whilst I'm still not amazing at it I am definitely getting better every time and am super proud of myself. My mum had even asked me to do hers for a wedding she's going to!

#at home nails#painted nails#therapeutic#at home therapy#uv cured#nail lamp#at home nail tech#improving every time#loving them

0 notes

Text

Josh Tonsfeldt Untitled 2022 Fiberglass reinforced gypsum, fiberglass cloth, epoxy resin, pigments, inkjet dyes, UV cured pigment print, silver gelatin print, dye sublimation print on polyester bed sheet, wood, bone, television components 27.75 x 49.25 x 3.25 in.

#Josh Tonsfeldt#sculpture#fiberglass reinforced gypsum#fiberglass cloth#epoxy resin#pigments#inkjet dyes#UV cured pigment print#silver gelatin print#dye sublimation#print#polyester bed sheet#wood#bone#television components#beige#pink

147 notes

·

View notes

Text

Trying to be patient and wait for resin to cure before adding more colors is actually torture to me I’m going to mcfucking die actually

#i LOVE doing resin#but also im gnawing my own leg off like a fox in a trap#‘you can use uv resin’#it is both more expensive to use uv resin for the molds im working with and also my molds aren’t clear so it won’t cure#epoxy resin is my best bet#it just takes sooooo long

56 notes

·

View notes

Note

Quinn with painted nails>>>>>>>

Yeeeees 🤧🤧💖 he has more patience than I bc I HATE painting my nails. So I always appreciate a cutie that puts the effort into theirs. They make his hands looks nice

#I do the lil pre-designed semi-cured gels that you finish off with a uv light#Quinn thirst tag#bb26#asks#anon

6 notes

·

View notes

Text

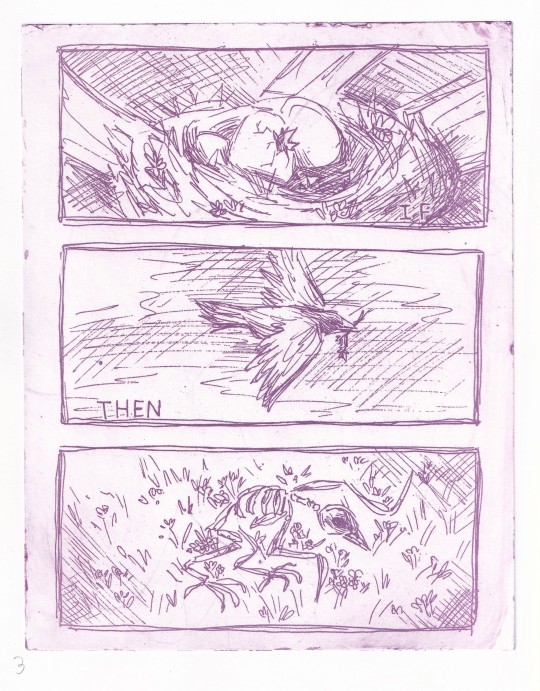

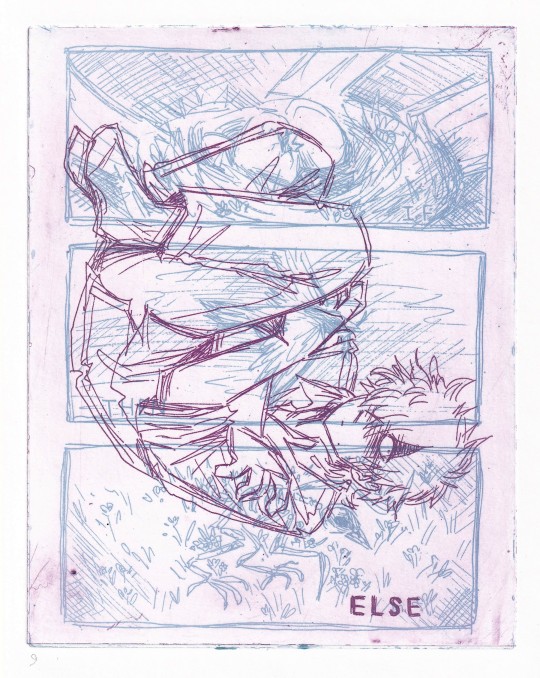

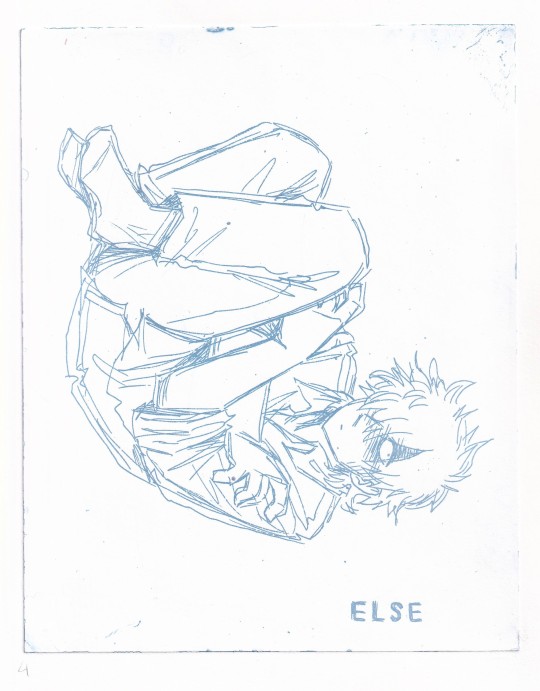

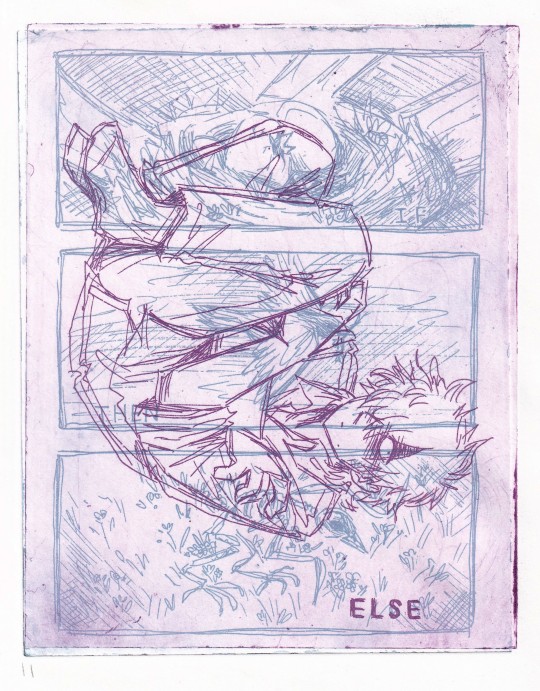

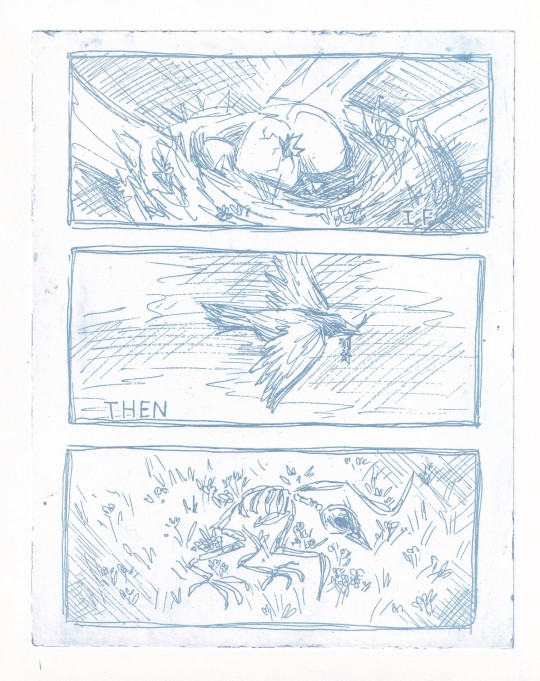

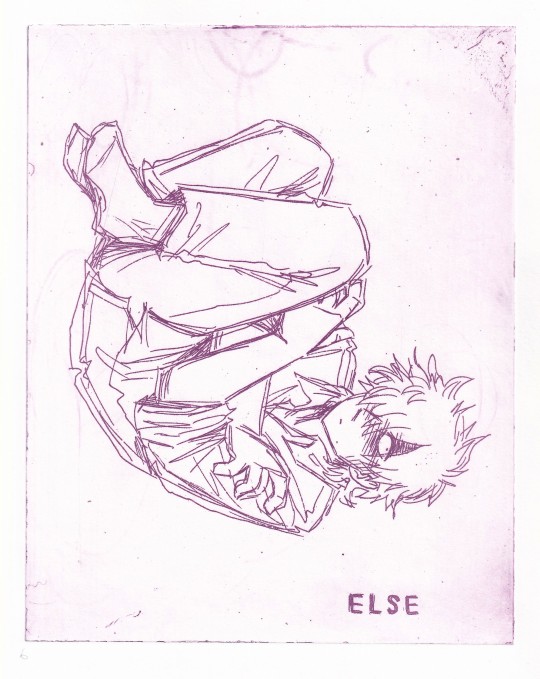

intaglio prints i did of my oc Dave for a class assignment like a year ago! a bit about Dave's feelings being a friendly but eternal, undying, and interdimensional sort of guy. being a little outside of the rest of the world's phase of reality, wanting to connect but knowing it can never last etc etc. was very fun!

#art#traditional art#printmaking#intaglio#done with like a vaguely photogravue-esque method: putting transparent film with drawings on a plate that has a photosensitive film over to#transferring the image via a uv light partial cure - removing the less cured parts (where the drawings lines were)#and then fully curing the film so its hard and can be used as a very low profile intaglio!#its very fun and fast - and thats why the drawings look so drawing-ly LOL they were pen drawings photocopied onto transparent paper#these were supposed to be like a sequential storytelling thing for the assignment where each plate was supposed to stand alone well#but i lost the plot half way through and made mine too intended to be layered so i understandably got docked a few marks for that LOL#BUT thats okay i learned a lot (1. remember the assignment instructions) and i still like these!#i should do more intaglio. i thought i hated it but then i realized the method for inking i was taught first was overkill#(i was taught to put way more ink than is needed and it took FOREVER to polish) but now that ive figured out easier methods#its really fun! and works well for someone like me who loves their sketchy lines

19 notes

·

View notes

Text

Soaking off my nail gel. Definitely did not shape the foil around my fingertips into claws so I could pretend to be Mephiles and make dramatic hand gestures. What a silly idea. I've never commited a shenanigan in my life.

#that was a lie#because I'm a liar#channeling my inner Kokichi#shenanigans#sillies#screaming my thoughts into the void#mephiles the dark#i wonder what grit of nail file you'd need for his claws#can he technically be used as a UV lamp?#i mean he emits the right colour#and he's supposed to be half of a sun god#imagine using Mephiles to flash cure nail polish#or resin#poke him once to activate the light poke twice to turn it off

9 notes

·

View notes

Text

Got some good nail polish so now I'm turning into a weekly self-manicure girlieboy.

Which tbh so far just means throwing out a bunch of my nail polish the day after I put it on because this stuff's quality is SO BAD now that I have some good ones for comparison

#WHY IS IT STICKY THE DAY AFTER I PUT IT ON????#its like a NIGHT AND DAY difference between the good and bad polishes#i don't understand why its like this for the life of me. it's explicitly NOT gel polish#so why is it just seemingly never fully curing? I am NOT getting a nail UV lamp#and like. who knows if the UV lamp would do anything consodering it js EXPLICITLY NOT GEL POLISH#ramblings of a bystander

3 notes

·

View notes

Text

thinking again about youtube commenters vs everyone else sfsd but i swear every holo taco/simplynotlogical upload there’s people asking for the polishes to be available as gels when 1) cristine has said she won’t do gel (and she’s never liked using it herself!!) 2) that’s like an entirely different production process…HT obviously is able to scale up enough to be available at (select location) ulta, but still….that’s a new production process with new rounds of product r&d and testing…i swear i never see people ask this of mooncat or ilnp…

#polish posting#it’s so. sfsds#i think it feels especially wild to me bc like#i recently ish rewatched some of the old simply videos where she does use gel#and she’s very vocal about not liking it#(she also calls the uv lamp curing the ‘cancer layer’ like i think this is smth she has strong opinions on lol)#and like. fair enough if you never watched her videos or anything but still…#like i said i feel like i don’t see it for other brands? so asking it from someone who has made it VERY clear she doesn’t like it is

3 notes

·

View notes

Text

I got toxic unlabeled UV resin from China on my hands and went to write a review on Amazon to help other crafters avoid this god awful excuse for UV resin..

Amazon said "Write four more reviews and we'll tell you a joke!"

This was the joke

#meme#fr tho my hands fucking hurt#and my whole crafting set up is FUCKED#because a company was allowed to sell UV Resin that doesn't cure and doesn't even have the same chemical properties as standard uv resin#and all i got was this damn joke

5 notes

·

View notes

Text

Best Budget Wash and Cure Stations

Post-processing is a big part of 3D printing in resin, and additional equipment, like wash and UV cure stations, is needed. In recent years, these two separate units started coming as two-in-one stations. Similar to 3D printers, washing and curing stations saw a few improvements with time, which made them more efficient with a better user experience.

2 notes

·

View notes

Text

How Paper Core Cutting Machines Enhance Industrial Operations

Machine bases are used in the industry for performing several tasks where accurate cutting of paper bases is required, be it packaging, labeling, and storage of products. Paper core cutting machines usually help in cutting paper tubes or cores of different sizes but executed precisely. Their use covers industries such as textiles, printing, and manufacturing, which helps to attain uniformity and minimize wastage of materials.

Latest paper core cutting machines integrate advanced automated control features, numerous blade options, and adjustable settings, to diverse requirements. Such machines are time-saving and even increase productivity, making them a precious gem of production lines.

At UV Graphic, we appreciate that for one's operation, precision and reliability matter a lot. Our paper core cutting machines are equipped with advanced technology to churn out high performance and durability for the cutting tools. Identify your needs, whether small scale to large industrial ones, as you seek us at UV Graphic-the right choice for you on all matters machinery, combining innovation with excellence.

#label punching machines manufacturer#uv curing systems#curing machine manufacturer#Paper Core Cutting Machine

0 notes

Text

UV Cured Acrylic Foam Tapes Market Trends Revolutionizing Construction and Assembly Processes

The UV cured acrylic foam tapes market has shown significant momentum in recent years, primarily driven by innovations in adhesive technology and the growing demand for versatile, high-performance bonding solutions. These tapes are designed with acrylic foam and cured using ultraviolet light, offering enhanced bonding strength, durability, and resistance to harsh environmental factors. As industries seek more efficient and reliable solutions for bonding and sealing applications, UV cured acrylic foam tapes are emerging as a preferred choice.

Key Trends Driving the UV Cured Acrylic Foam Tapes Market

Technological Advancements in Adhesive Solutions

One of the most prominent trends in the UV-cured acrylic foam tapes market is the continued evolution of adhesive technology. Manufacturers are focused on developing tapes with superior bonding strength, higher resistance to temperature fluctuations, and improved UV stability. This has resulted in the introduction of specialized UV-cured acrylic foam tapes tailored for a variety of applications in automotive, electronics, and construction. These advancements are helping to meet the increasing demand for high-performance bonding solutions, particularly in industries requiring durable, long-lasting adhesion.

Sustainability and Eco-Friendly Materials

As sustainability becomes a more significant concern across industries, the UV-cured acrylic foam tapes market is also undergoing changes to reduce its environmental impact. Manufacturers are increasingly using eco-friendly materials and developing processes that reduce energy consumption during production. UV curing, in particular, is considered a more energy-efficient curing method compared to traditional heat-based curing processes. This contributes to lower emissions and less resource consumption, making UV-cured acrylic foam tapes an environmentally friendly choice for companies aiming to meet sustainability goals.

Expanding Applications in the Automotive Industry

The automotive industry is one of the largest adopters of UV-cured acrylic foam tapes, with applications ranging from exterior bonding, sealing, and mounting to interior trim and noise reduction. The trend toward lightweight, fuel-efficient vehicles is driving the demand for tapes that provide strong, reliable adhesion while minimizing the weight of the final product. These tapes are also preferred for their ability to bond dissimilar materials, such as metal, glass, and plastics, which is essential in modern automotive design. As electric vehicles (EVs) and advanced vehicle systems continue to evolve, the demand for high-performance adhesives is expected to increase.

Increasing Demand in Electronics and Consumer Goods

Another major trend influencing the market is the rising demand for UV-cured acrylic foam tapes in the electronics and consumer goods sectors. These tapes are widely used in the assembly of electronic devices such as smartphones, computers, and televisions. They offer high-strength bonding for components like screens, touch panels, and internal parts, as well as excellent resistance to moisture and temperature variations. As consumer electronics become more sophisticated, there is a growing need for advanced adhesive solutions that provide clean, efficient, and durable bonding. The trend toward miniaturization in electronic devices also contributes to the increasing use of UV-cured acrylic foam tapes.

Focus on Enhanced Durability and Performance

Durability is a key factor driving the adoption of UV-cured acrylic foam tapes in several industries. These tapes provide exceptional resistance to UV light, moisture, chemicals, and temperature extremes. Manufacturers are focused on enhancing these properties further, allowing UV-cured acrylic foam tapes to perform in even the most challenging environments. This trend has led to the development of tapes that offer long-term performance in applications such as outdoor signage, building materials, and heavy-duty industrial equipment.

Global Expansion and Market Growth

As the global demand for UV-cured acrylic foam tapes increases, manufacturers are expanding their presence in emerging markets. The growth of industries such as construction, automotive, and electronics in regions like Asia-Pacific, Latin America, and Middle East & Africa is driving demand for high-performance adhesive solutions. In particular, rapid industrialization and infrastructure development in these regions are expected to further boost market growth. To meet this demand, manufacturers are investing in regional production facilities and expanding their distribution networks to ensure a consistent supply of UV-cured acrylic foam tapes worldwide.

Customization and Tailored Solutions

Customization is another growing trend in the UV-cured acrylic foam tapes market. Manufacturers are increasingly offering tailored adhesive solutions to meet the unique needs of different industries. Customizable features include varying levels of thickness, bonding strength, and resistance to specific environmental factors. This trend allows manufacturers to create bespoke products for clients in diverse sectors, from automotive and construction to electronics and consumer goods. As industries continue to evolve, there will be an increasing need for highly specialized adhesive products that cater to specific applications.

Challenges in the UV Cured Acrylic Foam Tapes Market

Despite the rapid growth and technological innovations, the UV-cured acrylic foam tapes market faces several challenges. One major obstacle is the high cost of production compared to other types of adhesive tapes. The use of advanced materials and UV curing technology often requires higher initial investments, which can make these tapes less affordable for smaller manufacturers. Additionally, while the market is expanding globally, companies must navigate regulatory challenges related to environmental standards and manufacturing processes.

Conclusion

The UV-cured acrylic foam tapes market is evolving with strong growth driven by technological advancements, sustainability, and a broadening range of applications. As industries demand more durable, high-performance adhesive solutions, manufacturers are meeting these needs with innovative products designed to withstand extreme conditions while promoting environmental responsibility. Moving forward, the trend of sustainability, coupled with global expansion and technological advancements, will shape the future of this market, offering new opportunities for companies and consumers alike.

#UV Cured Acrylic Foam Tapes Market#UV Cured Acrylic Foam Tapes#UV Cured Acrylic Foam Tapes Market trends

0 notes

Text

Complete Guide On Epoxy Adhesives For Silicon, Mixers, And UV Curing Adhesive Applicators

In many different sectors, adhesives have grown to be essential since they provide creative ways for bonding, sealing, and fixing. Among them, their great performance and adaptability make UV Curing Adhesive Applicator & Mixers and epoxy adhesives for silicone especially noteworthy. Modern technological developments guarantee accuracy, efficiency, and consistency in adhesive applications by means of tools such as UV curing adhesive applicators and mixers.

Describe UV curing adhesives

Specifically designed polymers that crystallise under UV radiation are UV curing adhesives. Photoinitiators used in these adhesives activate under UV light, causing fast cure and robust bond formation.

Characteristics of UV Curing Adhesives

Under UV light, solidify in a few of seconds.

Suitable for glass, plastics, and metals, versatile uses abound.

Clear finish: Perfect for looks.

Environmentally friendly: Models free of solvents lower VOC emissions.

Common Applications

Electronics: bonding circuits and components.

Medical instruments include catheters, syringes, and other tools that need sealing.

Optics: Arranging prisms and lenses.

The Function of UV Curing Adhesive Applicators and Mixers

UV curing adhesives require accuracy for best performance, mixers and applicators are indispensable instruments. These tools guarantee correct mixing and accurate glue application, therefore improving bond strength and dependability.

UV Curing Adhesive Applicators: Types

Simple tools for small-scale projects, perfect for prototype or repairs, manual applicants.

Designed for high volume manufacturing, automated applicators provide exact control over glue amount and application.

Applied for uniformly covering big surfaces are spray applicators.

Benefits of adhesive applicators

Reduced waste because to exact application.

Shortened application period, raised output.

Improved homogeneity for constant bonding quality.

Adhesives for UV curing mixers

Mixers guarantee even component mixing, therefore enabling adhesives to reach their full potential. Depending on the adhesive system and application needs, the most often employed varieties are static and dynamic mixers.

Knowing Epoxy Adhesives for silicone

Often needing specifically formulated adhesives like epoxy for bonding, silicone is noted for its flexibility and durability to severe temperatures. Designed to retain silicone's special qualities while forming robust, enduring bonding, epoxy adhesives for silicone.

Main Characteristics of Epoxy Adhesives for Silicone

Strong stickiness makes bonds even difficult surfaces efficient.

Resistance both chemically and thermally: can survive demanding surroundings.

Elasticity keeps flexibility to let silicone move.

Perfect for uneven or irregular surfaces are gap-filling capabilities.

Advice for Maximum Performance

Use effective curing UV light sources.

To stop early activation, keep adhesives cool and dark.

Calibrate applicators often to preserve accuracy.

Conclusion Modern answers in adhesive technology are UV curing adhesives and epoxy adhesives for silicone. In sectors including electronics, automotive, and healthcare, their fast curing, great bonding, and versatility make them indispensible. They provide unparalleled accuracy and efficiency when combined with modern instruments such UV curing adhesive applicator and mixers.

#Adhesive#Adhesives#Epoxy adhesive#Epoxy adhesives#UV curing adhesive#UV curing adhesives#Ultraviolet curing adhesive#Ultraviolet curing adhesives#Adhesive Applicator & Mixers#Adhesives for silicone

0 notes

Link

Curing coatings: A journey through the techniques and technologies used to transform liquid coatings into durable, protective films, from traditional methods to exciting innovations on the horizon.

0 notes

Text

Painted my nails last night before I went to sleep and must have done a poor job curing the gel bc my thumbs hurt :)

#like it woke me up at 5:45 bc it hurt so badly#I didn’t even file my nail beds so idk why they hurt so much#but reading online I guess it’s from being unevenly cured under the UV light

1 note

·

View note

Text

It could easily just be my nails I will acknowledge that but still as someone who has worn nail polish my entire life I don't tend to believe really any advice I'm given anymore in terms of not having it chip day one because personally I have only ever encountered one nail polish no matter what advice I followed or what brand I was using that did not chip day one

#my post#and it was this sparkly silver polish i found when i was in middle school at the dollar store#i'd put it over something else depending on what i had at the time and that shit wasn't coming off until i wanted it off#and i mean now i only use black nail polish and nothing else and with the look i tend to go for it doesn't matter if it chips#but still#i saw another post by someone who had a similar issue#and the comments were filled with shit i've tried that just did not work#and i've been told before that i could use gel polish but you have to cure gel polish#and given that the only color i wear most of the time now is black and given my current financial situation#i just do not have the money to spend on a uv lamp specifically to cure one gel polish color

0 notes